Goodbye, for now...

This update is long overdue. Unfortunately, due to the global COVID-19 pandemic, the MC-01 project is getting retired. However, we met many design and fabrication milestones between the last update in November and the present day. This post will showcase some of those moments.

Frame

The final motorcycle frame is incredibly rigid. The frame features a fully functional front and rear suspension system with a novel pivot system that resists suspension movement due to chain force. The frame also has multiple pickup points for the battery enclosure, surfboard style seat, and “gas tank” motor controller box.

3D Printed Jigs

Many features on the motorcycle frame required precise alignment. This was achieved through custom-designed 3d printed jigs/fixtures. I designed each jig to reference a common datum (primarily a welding table) and allow for torch clearance without warping due to heat. Jigs were used to position the head tube, bottom bracket pivot, brake mounting tab, and rear suspension points.

Rear Suspension

A concentric pivoting system is used for the rear suspension. This pivot system uses Delrin plain bushings to resist high thrust and normal loads. A bicycle bottom bracket shell is used as the pivot axle and allows the installation of bicycle cranksets. The swingarm bolts onto the bottom bracket shell through two CNC milled steel clamps.

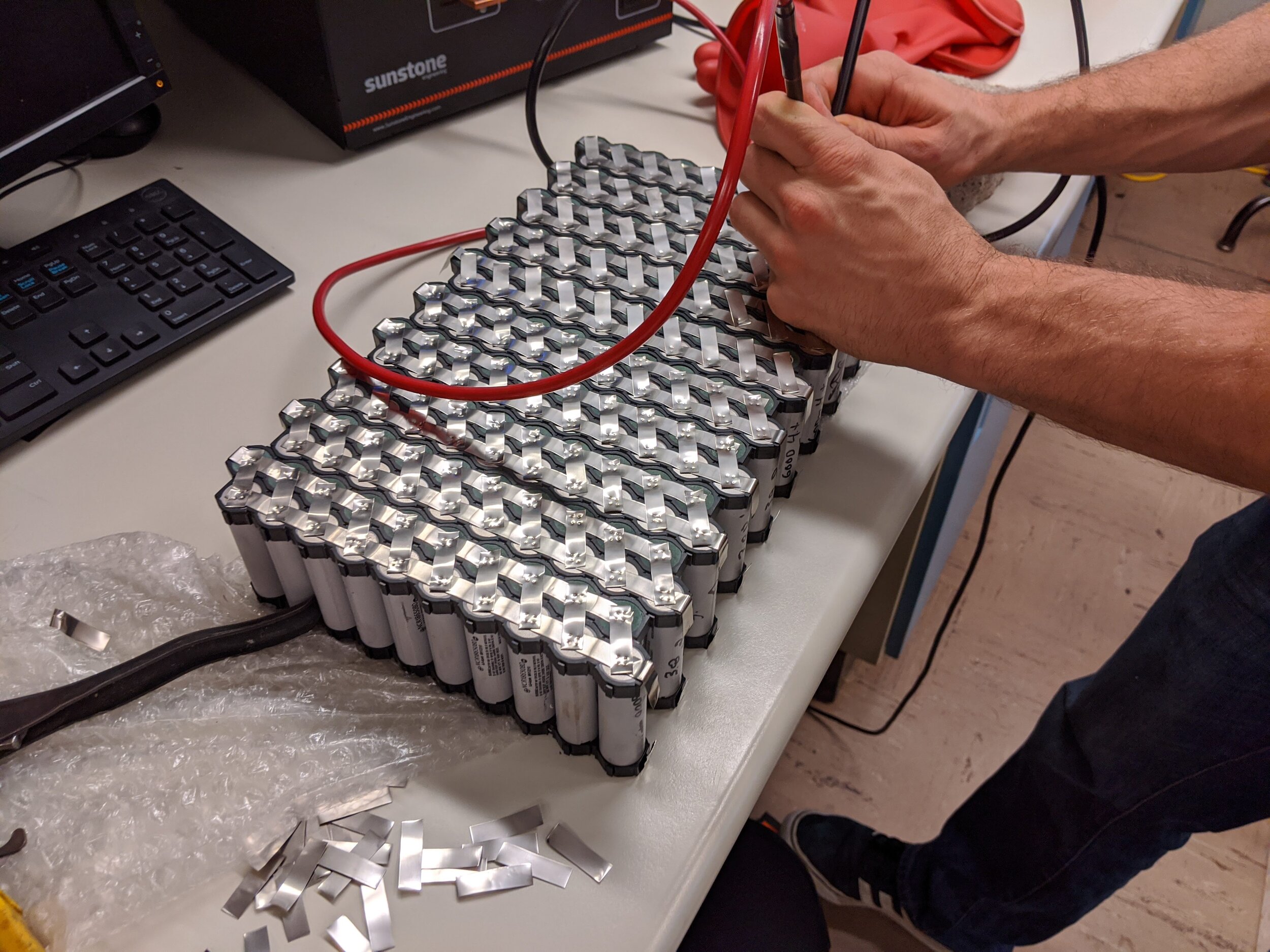

Battery Design

We used 200 18650 cells, recycled from electric cars, to make a 10p20s battery pack. We initially measured the voltage of each cell and created 20 banks of similarly charged batteries. After fully charging each bank, we spot welded the entire battery pack and integrated a BMS control system. Everything was then wrapped in heat shrink and foam for additional padding.