3d Printed Speaker case

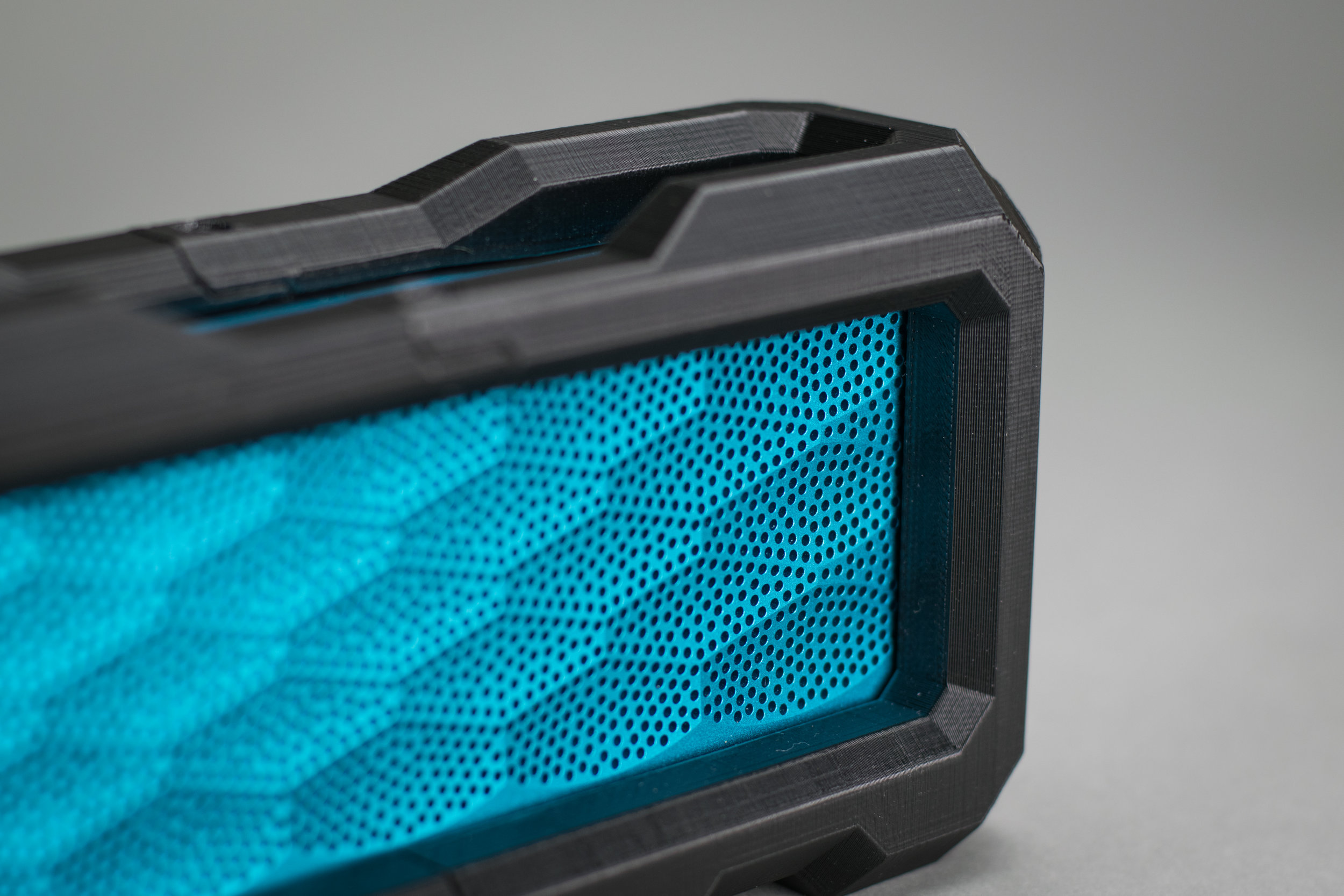

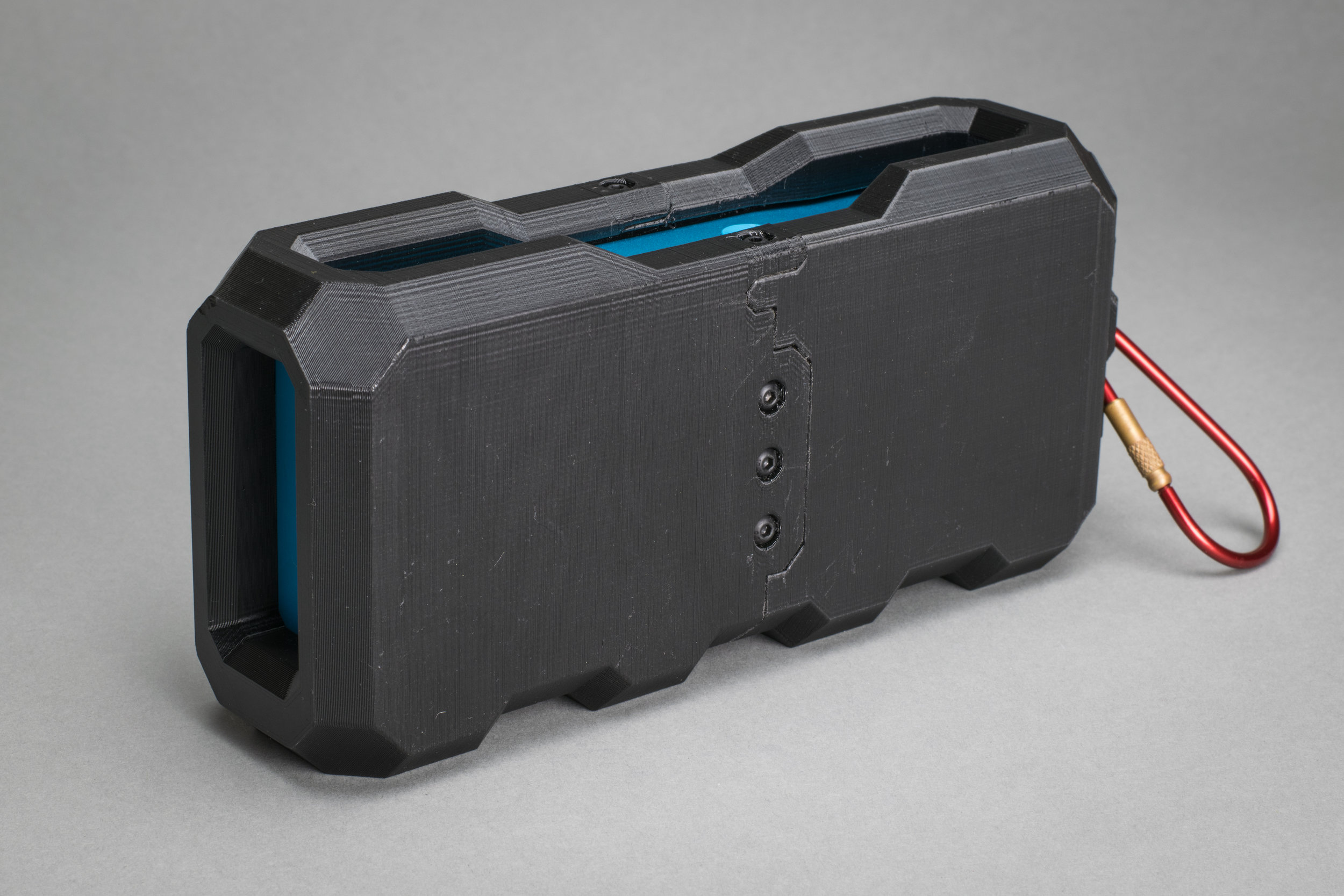

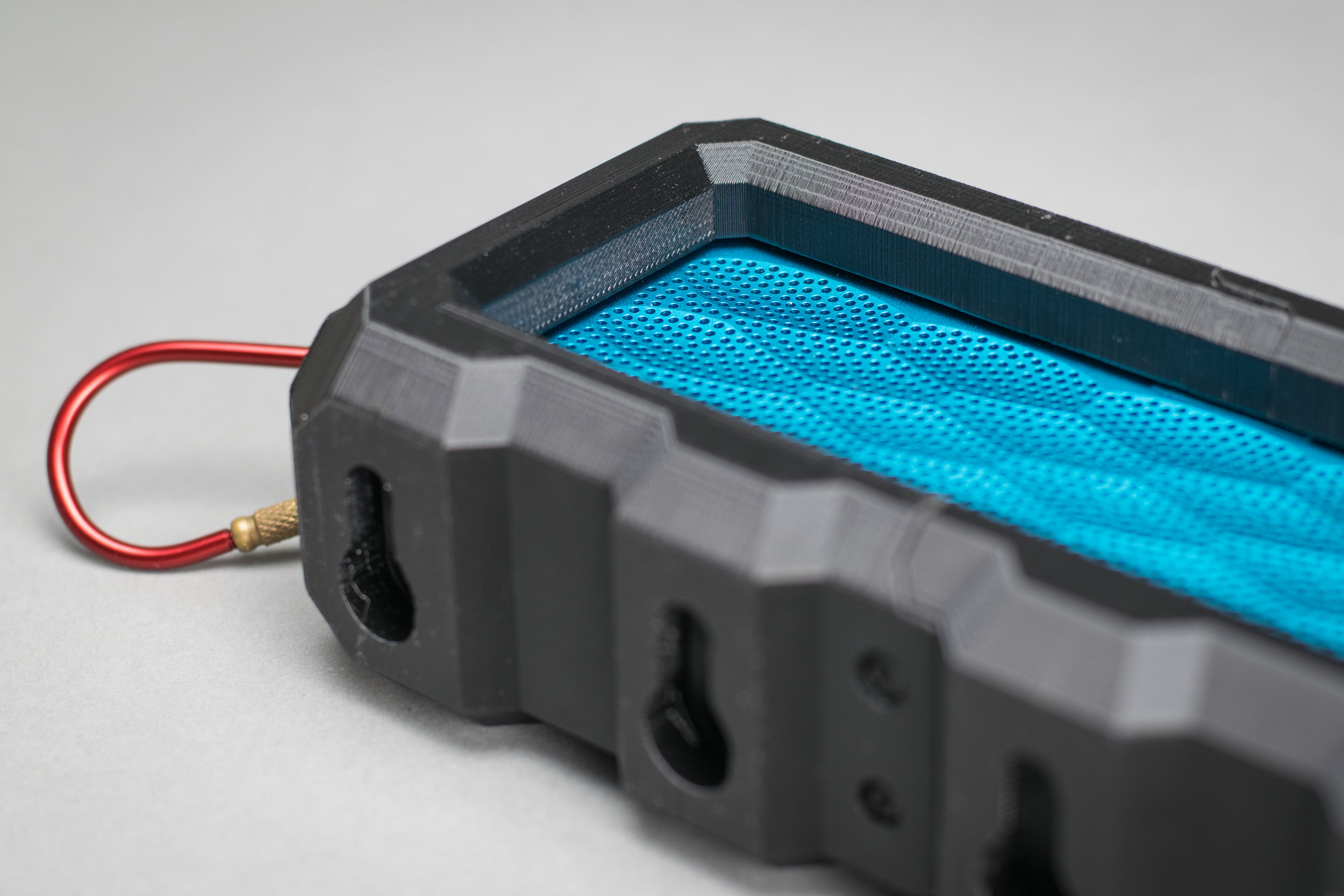

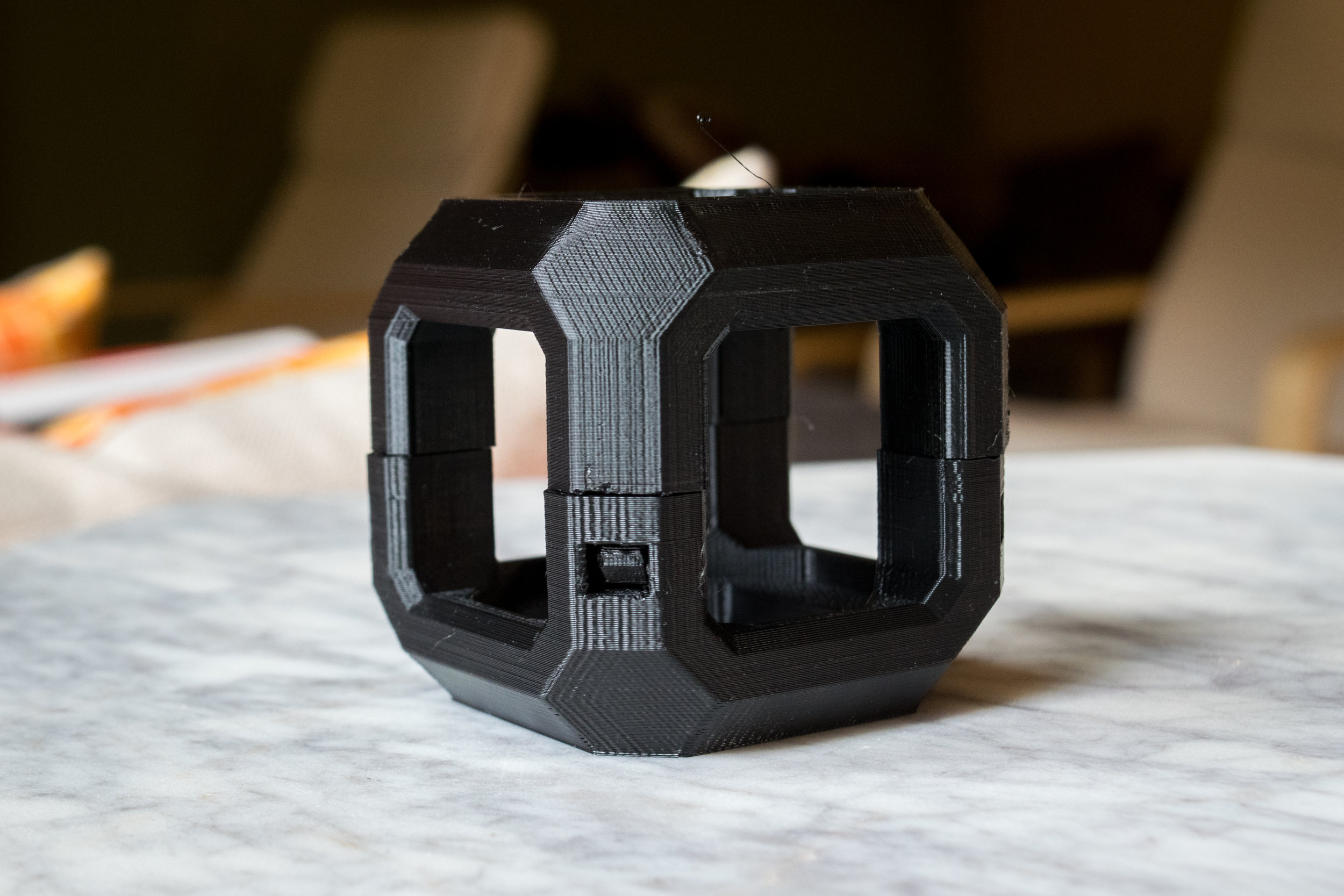

A durable exoskeleton type case for a bluetooth speaker. It features a highly versatile pin and slot mounting system as well as a carabiner mount and ridged grip for easy handling.

Printer: Prusa I3 Mk3 (Built/modified by me)

Skills Developed: 3D CAD for product design, Material Design, Design for 3d printing

Design Ethos: The design for this case took cues from various outdoor oriented products, with a polygonal shell creating a rugged, functional appearance. I also experimented with combining asymmetric elements, such as the carabiner mount and rear tooth mount, with symmetric details like the bottom and top ridges. The case is assembled using black oxide screws, which only furthers the core aesthetic.

Manufacturing Details: For the case material I chose PETG, a PET polymer blend with glycol for ease of printing. This material is relatively straight-forward to print with, and offers considerable impact, temperature, and UV resistance, all of which were important to the use case of this project. I experimented with several methods for assembling the two piece case design before deciding on using heat-set plastic inserts and fasteners, while testing different types of part densities to find the optimal balance of strength and weight.

Features: The case provides several advantages over the base speaker, while not obstructing any of its base features:

- Improved rattle resistance (as the speaker by itself is metal and conducts vibrations easily)

- Increased impact resistance over the speaker's thin sheetmetal body

- A pin/slot mounting system on the bottom of the case which allows it to be mounted virtually anywhere.

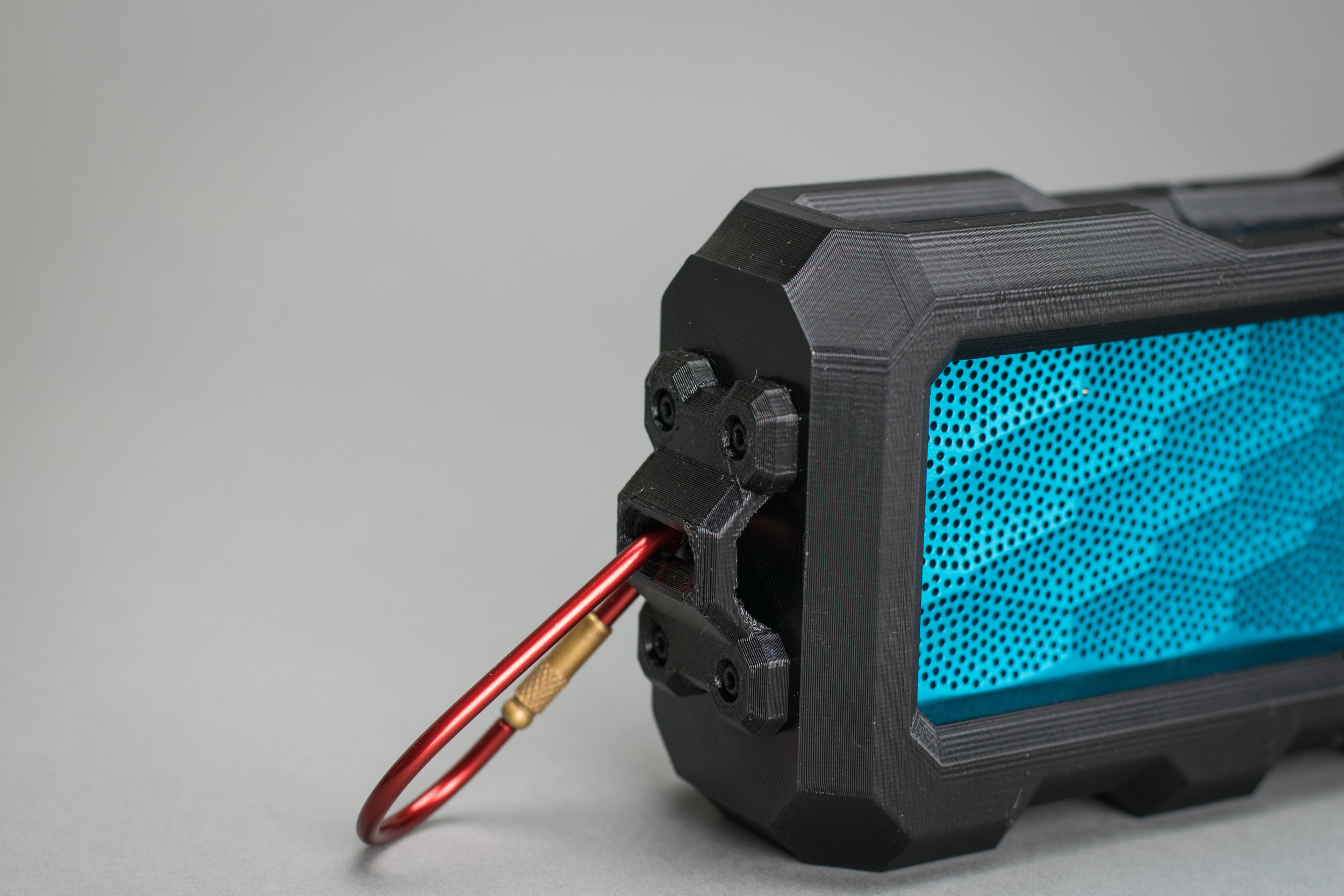

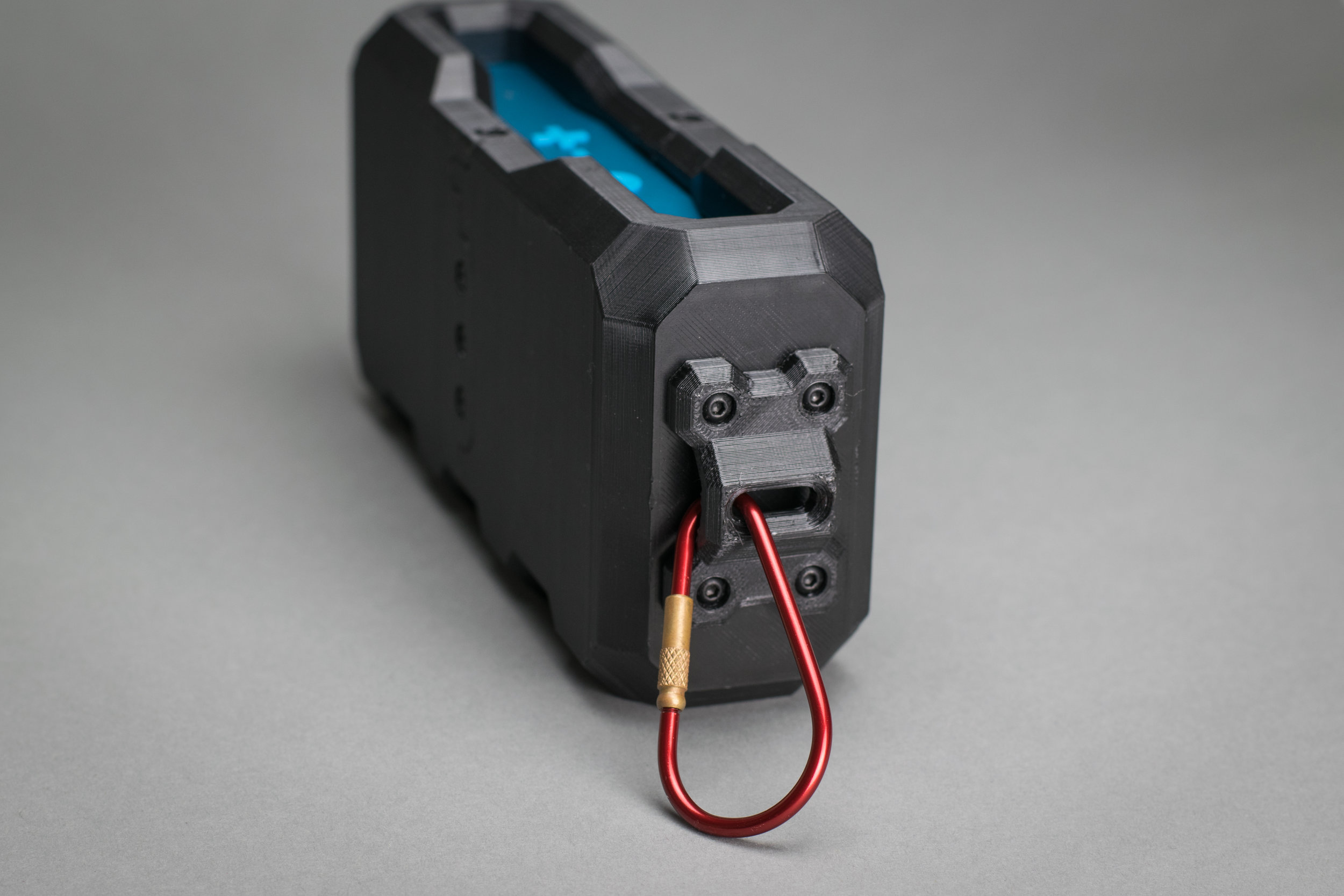

- Carabiner mount allowing the speaker to be attached to a backpack, belt, etc.

- Ridged bottom for a more comfortable grip compared to the slippery speaker body

DESIGN CHALLENGES

I originally envisioned a cantilever snap-fit design to hold the top and bottom of the case together. However, after testing various widths and thicknesses of cantilever with a small box, I realized that it was too weak (and usually sheared off the main case body). This could also be attributed to the anisotropic nature of 3d printed parts - since the layers are deposited horizontally, it is easy for them to shear apart if force is applied. In the end, heat-set inserts from Mcmastercarr proved to be the best solution.

Accessibility: All of the ports on the speaker are still accessible. I ensured that enough clearance was present to use touch all the buttons comfortably, and plug in cables with large diameter connector bodies without interference.

Carabiner Mount: The carabiner mount was printed with an increased infill over the rest of the case for increased strength. This makes it very easy to attach the speaker to a backpack or similar article.

Universal Mount: For the case's mounting system, I looked towards industrial storage racks and decided on the pin/slot system, for its security, durability, and ease of use.